LxE Gas Fired Low NOx Burners

Ideal for emission level compliance driven retrofits utilizing the existing fan, controls and pipe trains

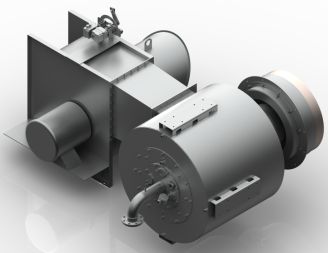

LxE Burner with remote mounted fan——LxE Burner with remote close coupled fan

Faber LxE Burners are gas fired, forced draft low emission burners for use with either a close coupled or remote mounted fan. These units operate at low excess air levels with turn down ratios up to 10:1. Guaranteed NOx emissions as low as 30 ppm without FGR and as low as 15 ppm with FGR, 50 ppm of CO, and trace amounts of VOC and particulate emissions on natural gas fuel. LxE burners are modular in design and consist of the following sub-components; a fixed geometry register, windbox, gas firing spuds, spark ignited gas pilot, two sight ports, flame scanner mount, three pressure tap ports and a refractory throat assembly.

Low Emissions, Modular, Flexible, Convenient Installation Options + Quick Delivery = Ultimate Retrofit Burner

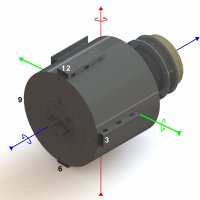

The LxE burner can be mounted either vertically up, vertically down or horizontally. Three universal mounting and lifting brackets are located around the burner housing allowing six points to bolt on burner supports and ancillary equipment. The air and gas supply connections can be located in any combination of 45º increments around the axis of the burner to suit site conditions. The entire burner assembly consists of thick steel fabrications designed to provide a long life of trouble free service. Two week deliveries are typical for units supplied with no combustion air fan. Six to eight week deliveries are typical for units supplied with a combustion air fan.

![]()

FABER LE = LOW NOx

Gas is fired through a single stage multiple spud system.

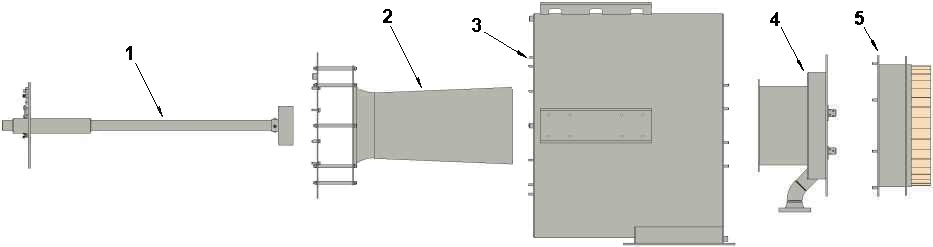

Faber LE Low NOx Burner – Operators Side, Side and Fireside Views

Faber LE Low NOx Burner – Combustion Air and Fuel Gas Connection Configurations Available

Faber LE Low NOx Burner – Exploded Side View

1. Burner Door & Diffuser, 2. Register, 3. Windbox, 4. Gas Ring and 5. Refractory Assemblies

Faber LE Low NOx Gas Burner Typical Specifications

Heat Input Range (MMBTU/hr) – 13 – 62

Maximum Draft Loss (inwc) – 4.1

Main Gas Supply Pressure (PSIG) – 10 – 12

Pilot Gas Supply Pressure (PSIG) – 0.75 – 2.5

Combustion Turndown – Up to 10:1

* Guaranteed Emissions:

NOx (ppm) – 50 no FGR

CO (ppm) – 50

VOC (lb/MMBTU) – 0.015

Particulate (lb/MMBTU) – 0.005

![]()

![]()

FABER L2E = LOWER NOx

Gas is fired through a two stage fixed center mounted gun and multiple spud system.

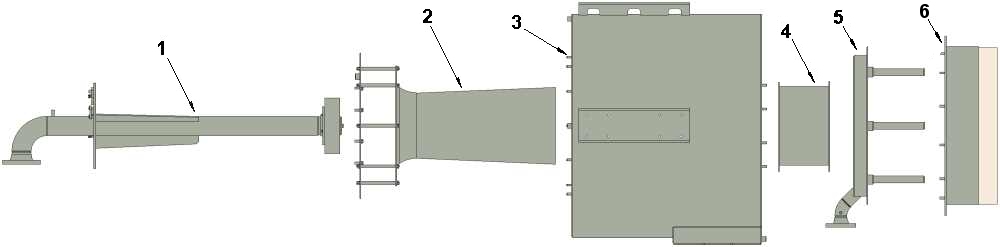

Faber L2E Low NOx Burner – Operators Side, Side and Fireside Views

Faber L2E Low NOx Burner – Combustion Air and Fuel Gas Connection Configurations Available

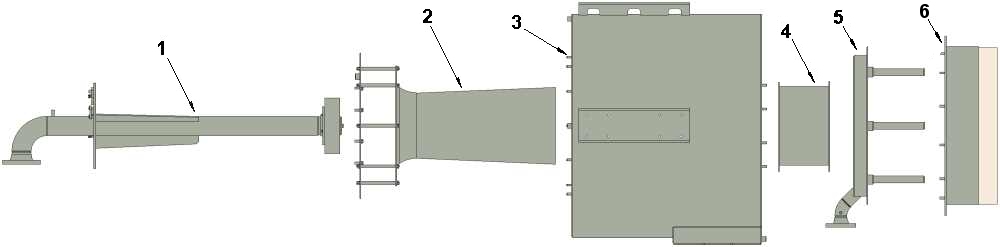

Faber L2E Low NOx Burner – Exploded Side View

1. Burner Door, Gas Gun & Diffuser, 2. Register, 3. Windbox, 4. Windbox Extension, 5. Gas Ring and 6. Refractory Assemblies

FABER L2E-SGB Low NOx Gas Burner Typical Specifications

Heat Input Range (MMBTU/hr) – 13 – 62

Maximum Draft Loss (inwc) – 4.1

Main Gas Supply Pressure (PSIG) – 10 – 12

Pilot Gas Supply Pressure (PSIG) – 0.75 – 2.5

Combustion Turndown – Up to 10:1

* Guaranteed Emissions:

NOx (ppm) – 30 – 40 no FGR

CO (ppm) – 50

VOC (lb/MMBTU) – 0.015

Particulate (lb/MMBTU) – 0.005

Easily converted to L3E-SGB burner for lower emissions

![]()

![]()

![]()

FABER L3E = LOWEST NOx

Gas is fired through a two stage fixed center mounted gun and multiple spud system +FGR.

Faber L3E Low NOx Burner – Operators Side, Side and Fireside Views

Faber L3E Low NOx Burner – Combustion Air/FGR Mixture and Fuel Gas Connection Configurations Available

Faber L3E Low NOx Burner – Exploded Side View

1. Burner Door, Gas Gun & Diffuser, 2. Register, 3. Windbox, 4. Windbox Extension, 5. Gas Ring and 6. Refractory Assemblies

FABER L3E-SGB-FGR Low NOx Gas Burner Typical Specifications

Heat Input Range (MMBTU/hr) – 13 – 62

Maximum Draft Loss (inwc) – 4.1

Main Gas Supply Pressure (PSIG) – 10 – 12

Pilot Gas Supply Pressure (PSIG) – 0.75 – 2.5

Combustion Turndown – Up to 10:1

* Guaranteed Emissions:

NOx (ppm) – 30 – 15

CO (ppm) – 50

VOC (lb/MMBTU) – 0.015

Particulate (lb/MMBTU) – 0.005

FABER LxE Gas Fired Low NOx Burner Accessories

Forced Draft Fan Assembly, FGR Dampers, Pipe Trains and Controls.

Round High Temperature Industrial Butterfly (FGR) Dampers

Pipe Rack Assemblies – Valve Trains or Individual Components

Burner Management Systems (BMS)

Combustion Control Systems (CCS)

* Results may vary contact factory for details